-

Shop Now

- SMR Target Holders

- Rock Steady

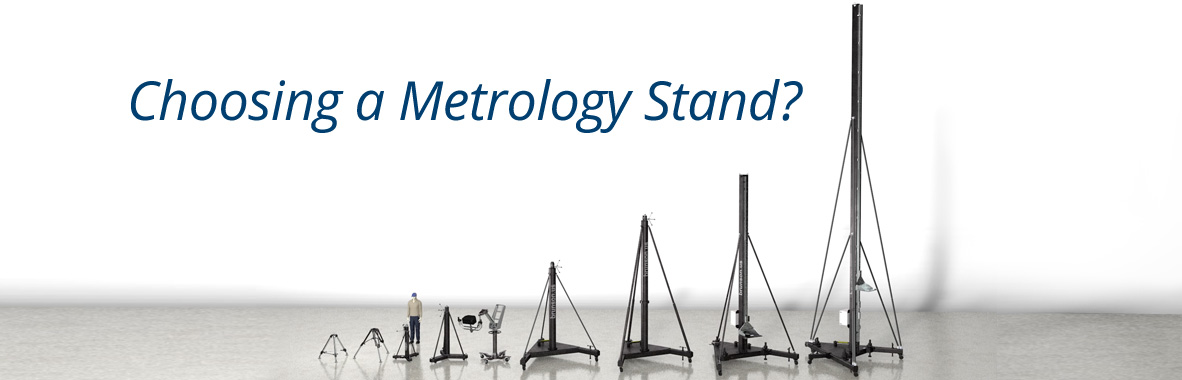

- BIG Metrology Stands

- Metrology Stands & Positioners

- KinAiry, Field Testing and Reference Bars

- Optical Instruments & Accessories

- Custom Solutions

- Services

- Contact

- Knowledgebase

- Rentals

- Blog

- Videos

- About Us

item(s) in your cart